Lower combustion furnace.

Fuel – wood in pieces, wood based products (materials), peat, sawdust, nutshells, woodchips, pellet.

Catalogue sheet for print

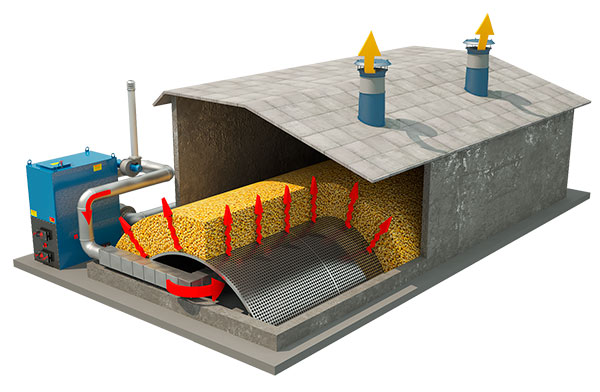

Furnace of type U over 350 kW with heat exchanger. Example of installation the furnace for drying cereal grain.

Furnace of type U up to 350 kW

Air transport elements visible on the photos are not standard equipment of the furnace.

Characteristics

Due to its unique, patented construction fuel combustion ratio is 92%.

The fuel is burnt in this furnace in two stages. In the first chamber gasification of the fuel occurs at a temperature of 700-800°C, and in the second chamber – complete combustion occurs as a result of the additional air inlet. Device efficiency reaches up 92%. Generated energy goes to the exchanger, whose construction and quality of workmanship guarantee high exchange capacity and a long-term use. This last feature has been achieved as a result of modern construction and construction materials resistant to high temperatures.

Intensity of fuel burnup is electronically controlled by a modern system adjusted to the specific operation of Robust furnace type U.

Versions of a Robust furnance type U

The furnace is manufactured in the following sizes: 30kW, 50kW, 100kW, 150kW, 200kW, 300kW, 350 kW, 500kW, 1000kW and marked respectively as:

U-30, U-50, U-100, U-150, U-200, U-300, U-350, U-500, U-1000

Advantages

Efficiency

The fuel is burnt in a furnace Robust type U in two stages. During the first stage the gasification of the fuel occurs and during the second stage – complete combustion takes place. Post-combustion effect is possible due to additional injection of air during the second stage of the process. Such combustion technology ensures very low gas emission into the atmosphere, which is important when we look at the issue from the environmental point of view – using the furnace we can protect the natural environment.

Energy efficiency of the furnace is 92%.

Reliability

Furnaces of series „Robust type U” are manufactured using modern technologies and high quality materials. Many years of manufacturing experience allowed us to develop a technically and manually advanced furnace that meets the expectations and needs of the market. Because of a combination of engineering know-how of our designers and operational experience we created a highly innovative product. High quality and efficiency is confirmed by a certificate issued by Polish and foreign scientific research institutes.60-month guarantee

We provide every furnace of „Robust type U” series with a 60-month guarantee.This includes technical assistance and full, specialised information about maintenance of the furnace and the hot air distributing installation – ITP.

Under the guarantee we assure delivery of spare parts along with their replacement as well as full service. One of the basic conditions of our 60-month guarantee is a necessity of carrying out an annual technical inspection by a client (the first inspection should be carried out between the 9th and 12th month of operation of the device). You may find all specific issues related to the guarantee and its conditions in Operation and Maintenance Manual (DTR) supplied with the device.

Savings

Heating with Robust type U blow-in furnace is currently the most economical and effective way of providing heat to heated rooms.Due to its characteristics these furnaces are ideal for heating industrial, sports, commercial, sacred and gardening facilities as well animal farms, poultry houses, workshops and all kinds of drying facilities and devices (wood, sawdust, cereal, corn, herbs, etc.) Another important feature of this furnace is the fact that it can burn different kinds of solid fuels, from wood and pellet, through sawdust and dust to all wood based waste. This device can heat large surfaces in a short time and we may turn it off at any time, which gives big savings in fuel consumption and does not require the user to maintain minimal temperatures in times when particular rooms are not used. Another advantage is its simple, failure-free, self-operating and very economical hot air distributing installation (ITP).

Application

Furnaces of this type are ideal for heating of industrial, sports, commercial, sacred and gardening facilities as well animal farms, poultry house, workshops and all kinds of drying facilities and devices (wood, sawdust, cereal, corn, herbs etc.)In furnaces with a power output ranging from 500 kW to 3000 kW a heat exchanger is made of heat-resistant materials in order to reach temperatures of hot air ranging from 100 °C – 200 °C.

In the times of financial crisis and very significant increases in gas, diesel fuel and coal prices a specific problem occurred: how to heat rooms both effectively and economically? It is particularly onerous for businessmen who are the owners of big plants, greenhouses, poultry houses, dryers etc. These buildings need a lot of heat energy, and cost of producing heat energy has a substantial impact on production costs, which makes products uncompetitive.

Furnaces of „Robust type U” series provide a lot of heat using relatively cheap kind of fuel – wood in pieces, wood based products (materials), sawdust, woodchip, nutshells, peat, corn cobs, briquette, pellet etc.

Due to the modern construction fuel combustion ratio is 92%.

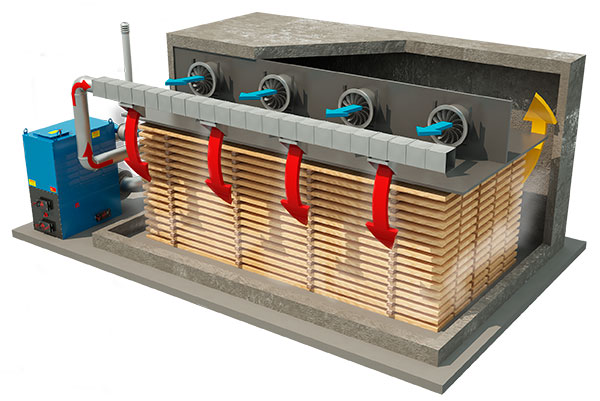

Timber drying kiln based on Robust type U

Cereal drying room based on Robust type U

Technical data

| Robust furnace |

Typ | U-30 | U-50 | U-100 | U-150 | U-200 | U-300 | U-350 | U-500 | U-1000 |

| Device power | kW | 30 | 50 | 100 | 150 | 200 | 300 | 350 | 500 | 1000 |

| Maximum temperature of air supply* | °C | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Smoke conduit | mm mm |

170 170 |

170 170 |

170 170 |

200 200 |

200 200 |

250 250 |

250 250 |

250 250 |

300 300 |

| Chimney diameter | mm | 180 | 180 | 180 | 200 | 200 | 250 | 160 | 250 | 300 |

| Capacity of the fuel chamber | m3 | 0.25 | 0.25 | 0.35 | 0.55 | 0.65 | 0.72 | 1.0 | 0.8 | 2.0 |

| Amount of heated air | m3/h | 1000 | 1700 | 3200 | 4800 | 6400 | 9600 | 10000 | 16000 | 32000 |

| Dimensions – width | mm | 1180 | 1180 | 1280 | 1440 | 1500 | 1620 | 1500 | 1730 | 1600 |

| Dimensions – height | mm | 2170 | 2170 | 2240 | 2350 | 2540 | 2540 | 2500 | 2200 | 3000 |

| Dimensions – depth | mm | 1730 | 1730 | 1880 | 2340 | 2630 | 3220 | 3000 | 5000 | 6000 |

| Weight | kg | 750 | 850 | 1100 | 1300 | 1600 | 2000 | 2200 | 5000 | 7500 |

| Motor of the combustion gas fan | ||||||||||

| Power | kW | 0.25 | 0.25 | 0.37 | 0.37 | 0.37 | 0.55 | 0.55 | 1.1 | 1.5 |

| Supply voltage | V | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 |

| Motor of the main fan | ||||||||||

| Power | kW | 0.75 | 2.2 | 3.0 | 4.0 | 5.5 | 2x4.0 | 2x4.0 | 18.5 | 30 |

| Supply voltage | V | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 |

| Parameters of heated rooms | ||||||||||

| Cubature for h=4m | m3 | 230 | 370 | 750 | 1130 | 1500 | 2300 | 2600 | 3700 | 7500 |

| Cubature for h=3m | m3 | 300 | 500 | 1000 | 1500 | 2000 | 3000 | 3500 | 5000 | 10000 |

* The temperature of air supply depends on calorific value of fuel and applied heat exchanger. The table contains maximum temperature of air supply.

Warranty

- We hereby grant a 5-year guarantee on subassemblies manufactured by our company.

- The contractor undertakes to fulfil its obligations under the guarantee within:

– 7 working days form the date it is confirmed (via electronic mail or fax) that the relevant spare part necessary to remove the defect is available on the territory of the Republic of Poland,

– 14 working days form the date it is confirmed (via electronic mail or fax) that the relevant spare part necessary to remove the defect is available on the territory of the European Union,

– 28 working days form the date it is confirmed (via electronic mail or fax) that the relevant spare part necessary to remove the defect is available outside the territory of the European Union.

Price list

In order to obtain information about the prices, please contact us at the following phone number:

+48 604 47 62 14

Upon a client's demand, we prepare a project design and a specification of the air distributing installation (ITP) against payment.

We provide assistance in the purchase of fittings (ITP) as well as in the installation assembly.